Membrane BIOREACTOR (MBR) MEMJET

the MEMJET process is based on this energy efficient submerged membrane filtration.

MBR-Test unit

As a result of variable qualities and pollution of different waste water, it is strongly recommended to test on site.

The container plant is designed to test variable types of membranes (hollow fibre modules, plates modules and spiral modules, etc.) from different manufacturers with various operation methods and Dead-End or Semi-Cross-Flow.

MEMJET treatment

The filtration area of one technical module is 105 m2. 3 modules are assembled to form a row. The hollow fiber membranes are stretched between 2 permeate collection pipes with a specified over length in order to allow them to swing in the up flowing mixture of air and biomass.

Membrane

The MEMJET process is equipped with a submerged commercial hollow fiber membrane with a cut-off of 0,4 µm and with an outer diameter of appr. 540 µm. The membranes are made of polyethylene and they are permanently hydrophilic. The fibers are highly resistant to flexural fatigue. The membranes can be stored dry and do not need to be pre-wetted prior to use.

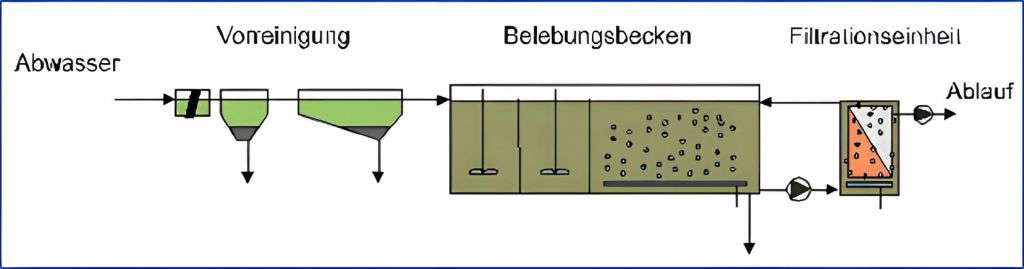

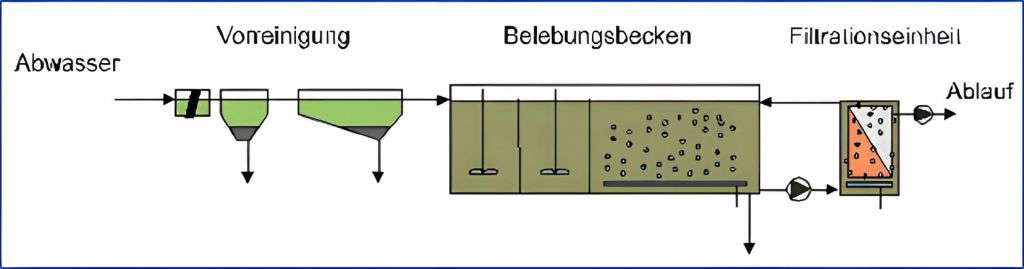

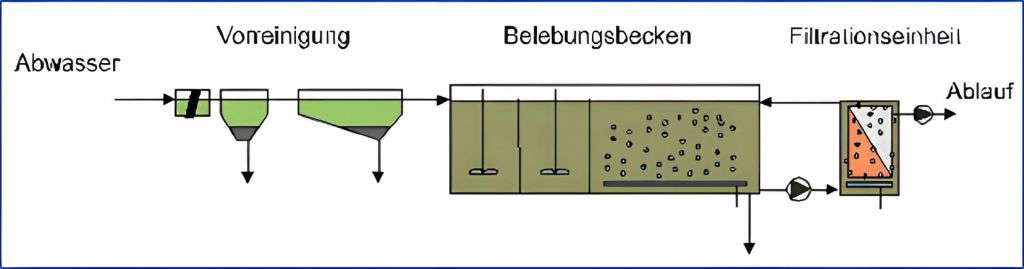

Membrane bioreactor (MBR)

An aeration device below the membranes provides an air-stream and thus a coupled hydraulic flow along the membrane surface. The cleaned water is filtrated through the fine pores of the membrane (= permeate) and flows through the hollow fibers to two permeate pipes. The hydraulic flow and extraction of the permeate is achieved through a suction pump or slight hydraulic pressure gradient and is therefore energetically highly efficient (appr. 0,12 kWh/m3).

- Smaller treatment volumes – savings on land

- No wash-out of biomass due to 100 % withdrawal of biomass on membrane surface

- Enhanced biological degradation due to highly specific biomass and high sludge age

- No influence of peak flows on quality of permeate (= clean water)

- Germ free effluent